Hard metallic materials cannot be molded for commercial purposes. Steel, aluminum, stainless steel and other have the characteristics of hardness that even when they are subjected to hard objects through pressing and stamping would be hard to shape.

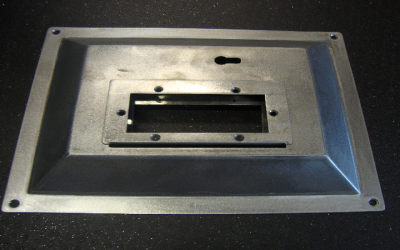

These metals need deep drawing. It is a manufacturing process where the sheet metal undergoes a mechanical process. After the stamping process, what you get is a stronger deep drawn metal that exhibits superior strength. This process can also produce different parts from intricate, symmetrical and even asymmetrical parts.

The deep drawing process includes various steps and components. For one, it includes the materials that will be used for deep drawing, the characterizing of stampings, deep draw presses, the station types and how the raw material undergoes all of these processes before finally having a strong deep drawn metal.

Characteristics of Deep Drawn Metal

Deep drawn metals possess certain characteristics. For instance, they have thicker wall variation. The consistency may vary as some will have to undergo secondary processing. Raw materials undergo the deep drawing process where they surface is stretched and undergo treatment to increase its strength. In the process, it doesn’t allow radii that are sharp.

Main Types of Stamping Presses

In metal deep drawing process, there are 3 main types of stamping presses that are used which include the following:

ICOP: Also known as the Individually Cam Operated Press, this process installs die components in the press for every station, one at a time.

Progressive Die Press: With this type of stamping press, the metal undergoes steel webbing until it reaches the forming process.

Die-Set Transfer Pres: Compare to the previous stamping type, the tools are also included in the die plates. As such, the die are installed in the press.

Station Types

Apart from the mentioned stamping presses, there are other additional processes including the stations which include:

Blanking: In this process, the sheet is cut into a flatter shape which is needed for deep drawing.

Drawing: After cutting out the metal, it proceeds to the next station where it undergoes a punch and die process which forms the metal.

Piercing: This is part of the process that punch in holes in the metal which are important for the the finished output.

Trimming: To remove the excess metal, it undergoes the trimming process. This is essential to remove any excess and remove unnecessary part.

There are plenty of Metal Deep Drawing Companies in the market today. Gasser & Sons has a professional metal deep drawing process that is cost efficient while production speeds remain higher than in any other processes. To know more call 631-503-3192