In brazing, two or more pieces of metals are joined by means of flowing a filler metal between the joint interfaces. The temperature is below the melting point of the base metal but above 900°F. In the aluminum dip braze, the filler metal is basically 88% aluminum and 12% silicon.

Brazing-aluminum Basics

In brazing aluminum, you have to keep two facts in mind for a successful application:

- The aluminum oxide interferes with brazing as it forms easily on the external surface.

- The brazing temperature is dangerous as it is close to the melting range of aluminum alloys.

From this information, you have to eliminate all existing aluminum oxide prior to the brazing and prevent its renewed formation while heating, and control precisely the heating cycle. Most common of the aluminum alloys are brazeable and capable of being wrought, extruded or cast form. Aluminum die castings are not brazeable due to their high gas content that causes blistering on the surface. Filler metals used as filler metals used in aluminum dip braze are aluminum silicon alloys.

Procedure

1. Clean off excess oxides, and then assemble parts applied with the proper filler metal. The form of filler alloy is varied to suit the type of joint. The achieved precision in this process has excellent control over excess flow of filler metal.

2. Place the stainless steel fixtures and heat to 985°F in a pre-heat furnace and then immersed in a bath of molten salt that contains a flux. The molten flux at 1100°F serves for multi-purpose role:

- Providing heat transfer

- Supporting the assembly

- Fluxing the joints.

Time for immersion is variable but it is generally less than two minutes

3. During the course of this cycle, melted filler metal flows to all joints via a capillary action. The assembly is removed from the bath, cooled, and cleaned; ready for further processing.

Advantages of aluminum dip braze

- Tooling cost reduction.

The dip brazing process uses little if any specialized tool. Fixturing is generally accomplished with common fixtures that allow for quick and inexpensive configuration changes.

- Savings on materials.

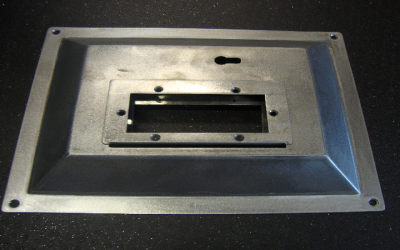

Unlike castings or machined parts, dip brazing can be done at near net size.

- Improvement of structural integrity.

Aluminum dip braze offers a continuous leak-tight and shielded EMI joint including several thickness of materials.

- Conductivity improvement.

The design engineer will enjoy a greater range of options

As the dip brazed joint is aluminum, conductivity is relatively an improvement than the use of mechanically attached assembly or adhesive bonded.

- Lesser distortion.

All components are uniformly heated in the braze process with less distortion than that of the welded part.

- Lowered cost.

All the characteristics achieved is superior, dip brazed process still cost the lowest.

- Freedom of design.

There will be a wider array of options that the design engineer will enjoy when he uses the dip brazed process.

Results of aluminum dip braze are always positive as it provides an effective practical solution in joining metals for varied purposes.

Hi-Temp Brazing Inc. provides professional Dip Brazing Services . They are NADCAP accredited for 12 years in all requirements of aluminum dip brazing and related services.