There are many different pieces of equipment out on the market now, all of which can help you get your product manufactured with ease. However, without the right preparation and research, you might end up choosing the wrong Plastic Injection Molding machine. To help you avoid making this expensive mistake, read on to find some great tips and tricks when selecting the right one.

Make Sure You Know What Plastic Parts You’re Making

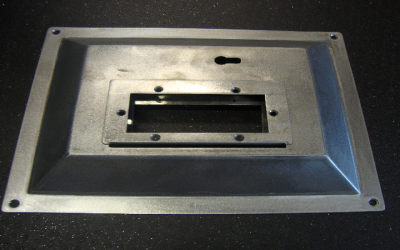

What type of plastic material are you going to use? How heavy will the parts be? What are the exact dimensions of the parts? Don’t forget about the mold, either. How big and how heavy will the mold be? Only with all of this information in mind will you be able to figure out how much tonnage you need.

Pick the Right Type of Machine For Your Needs

There are three main types of machines used for these purposes. A fully hydraulic machine does not use up that much power when compared to an electric machine. A fully electric machine may use up more power, but can guarantee consistent part quality. A hybrid machine combines the features of a hydraulic machine and an electric machine into one.

Figure Out How Much Tonnage You Need

If you get the wrong tonnage, then you’ll end up with parts that have inconsistent weights and sizes. These parts will also have very poor surface finishes, too. You will also end up wearing out your machine prematurely. If you aren’t sure what you need, try contacting a reliable company like I.F. Associates, Inc. for some help.

Finding the right machine may take a lot more time and effort, but it will definitely pay off in the long run. Make sure to ask as many questions as possible whenever you’re calling up a potential provider. Do your research thoroughly enough, and you should be able to get the best Plastic Injection Molding in New Jersey.